That’s auto manufacturing for you. It's not just about putting wheels on a frame. It is a deep and coordinated process. It consists of thousands of parts, people and systems - working together to bring vehicles into life.

What is Auto Manufacturing?

In the simplest sense, it is the process of designing, assembling and producing cars. But it's more complicated than it looks. Each car has a large -scale operation: Design team mapped the structure and aesthetics, engineering -technical matrix, and delivered moving parts across the country.

And of course, the machines that work faster than humans. Still, even with all the tech, there’s something oddly human about it. Real people still test drive prototypes. They inspect paint finishes with their own eyes. And they tweak software in real time based on feedback.

How Cars Are Made: A Quick Look at the Production Flow

Let’s walk through the automotive production process—not the textbook version, but the way it actually feels when you’re in it.

Step 1: Sketch It Out

It starts on paper—or rather, on a screen. Designers pitch ideas, draw outlines, and debate over features. They care about how it looks, but also how it moves. Will it slice through the wind? Can it handle bumpy roads?

Step 2: Building a sample

This is the first full version of the car, just not for sale yet. It’s where kinks are worked out, safety is tested, and decisions are made about what stays and what gets cut.

Step 3: Hit the Vehicle Assembly Line

Now things get loud. Chassis meet engines. Wiring gets installed. Parts snap into place. Some hands are robotic. Others are gloved and human.

Step 4: Make It Look Good (And Protect It)

Once the body’s all together, it heads to the paint booth. Now, you’d think this part is mostly for looks, right? But actually, there’s more going on. The paint job? It’s also armor. Layers of primer and finish help the car fight off scratches, rust, and sun damage. So yeah—it’s fashion and function. This is also when custom colors get added. Some brands offer deep, glossy reds or stealthy matte finishes. Pretty cool to see.

Step 5: Tast, Test, and Then Test Again

No car gets to leave the factory without a bunch of checkups. Lights, brakes, steering, airbags, electronics—you name it. There’s no room for "maybe it’s fine." Every part has to work perfectly. Otherwise, it doesn’t make it past the line.

Read more:- Passenger Vehicle Trends in Kerala 2025: EVs, Tata, Mahindra & More

Car Manufacturing Companies: Who’s Really Running the Show?

Toyota, Ford, or Tesla are some world renowned brands. But here’s the thing. These car manufacturing companies aren’t just brands.

These companies are investing in research and development to find out how to build produce efficiently. Some are shifting to fully electric lines. Others are using AI to cut down on waste and speed up production. Honestly, car manufacturing companies today are more like tech firms with wheels. They're always upgrading. Always adapting.

Who Actually Builds All the Tiny Parts?

Here’s something most people don’t think about: car brands like Ford or Toyota don’t build everything themselves. In fact, most of the parts come from third-party businesses called automotive component suppliers.

They specialize in stuff like:

- Infotainment systems

- Brake pads and rotors

- Electronic sensors

- Side mirrors

- Interior panels

Some factories get these pieces delivered just hours—or even minutes—before they’re installed. It’s a dance of timing and trust.

The Vehicle Assembly Line Up Close

If you walked into a modern vehicle assembly line, you'd see a kind of organized chaos. One side’s fitting windshields, another is mounting seats, and yet another is checking engine functions with digital screens. The key? Timing. Every station has a specific task, and the car moves like clockwork from one point to the next.

And it’s not just robots. But real people are still there. Adjusting details. Fixing something the machine couldn’t quite get right. Catching flaws a sensor missed.

Smart Manufacturing Is the New Normal

Factories today aren’t just loud and oily. Many are silent in parts, lit by LED panels, with robots gliding smoothly across floors. Welcome to the age of smart manufacturing.

Think:

- Real-time sensors checking temperature and pressure

- Predictive systems flagging part issues before they happen

- Robots that know when to slow down or speed up based on demand

- Software adjusting entire production lines based on what’s selling

It’s wild. And it works.

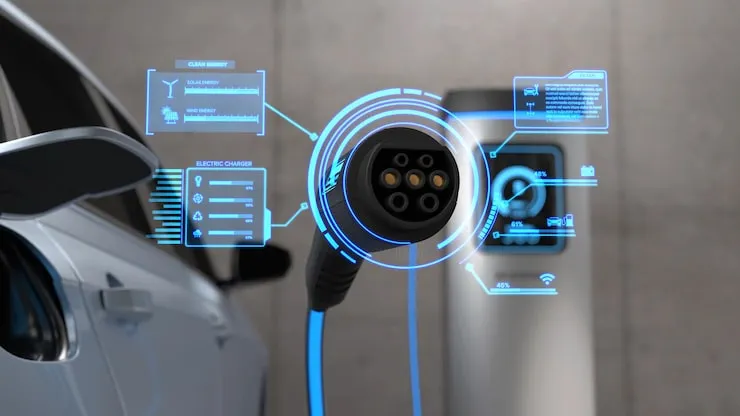

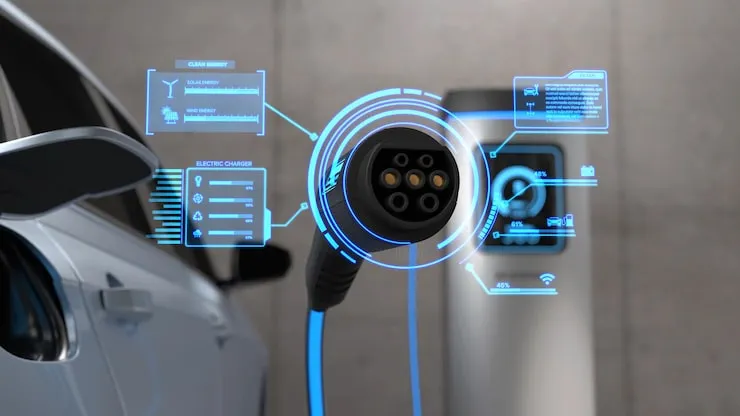

Electric Vehicle Production: A Whole New Game

Now let’s talk about EVs. Fewer moving parts. No exhaust. Giant batteries instead of fuel tanks. That changes everything in manufacturing. Plants now need clean rooms for battery packs. Engineers are focused on efficiency and cooling. Charging ports, software updates, regenerative braking—these weren’t even topics ten years ago. And the demand? Skyrocketing. Companies like Tesla made the spark, but now everyone's catching up. Even old-school automakers are converting entire facilities just to keep up.

The Pressure on Suppliers Just Got Real

With EVs on the rise, automotive component suppliers have had to step up their game. Now, instead of designing things like mufflers and gearboxes, they’re making:

- Battery modules

- Fast-charging ports

- Lightweight aluminum parts for better range

- Cooling systems for power units

It’s like everyone had to learn a new language overnight—and the ones who adapted fastest are winning contracts left and right.

The Struggles Behind the Scenes

Of course, nothing's perfect.

Let’s be real:

- Chip shortages have shut down production lines worldwide

- Shipping delays mess with tight schedules

- Material costs are up (like steel and lithium)

- New environmental laws are forcing factories to rethink everything

Companies are juggling all this while still trying to pump out more cars than ever. It’s intense.But the ones that stay flexible, automate smartly, and build local partnerships? They’re managing just fine.

Where’s All This Going?

Here’s where auto manufacturing seems to be headed:

- More personalized cars – Want a purple steering wheel with gold trim? Might be an option.

- 3D-printed parts – Already happening for rare components.

- Fully automated EV-only plants – Built from scratch to produce just electric cars.

- Factories powered by wind or solar – Sustainability’s no longer a bonus—it’s expected.

- Smarter software – Cars that update themselves overnight, no mechanic needed.

We’re not just building vehicles. We’re building tech hubs on wheels.

So, Why Does Auto Manufacturing Still Matter?

Because everything moves on wheels. Whether it is a delivery car, family car or public bus. Each type requires auto manufacturing. And as cars evolve, so does the process behind them. One thing’s for sure: it’s never standing still.